Process

1. GRAPHICS REPRODUCTION

In house pre-press department uses a specified packaging and planning software like Artpro, Pac Zed, High Quality Hinting Pro (HQH Pro), color management software & tools like high resolution graphics displays & printer technology assisted by Apple, Epson to meet gravure printing requirements. The designer performs tests like color separation, resolution, auto trapping & bar code generation. Highly experienced and industry professionals spin their magic on color calibrated monitors for optimum halftone result. The design is then physically checked with the digital proof and assured by the pre-press head for production.

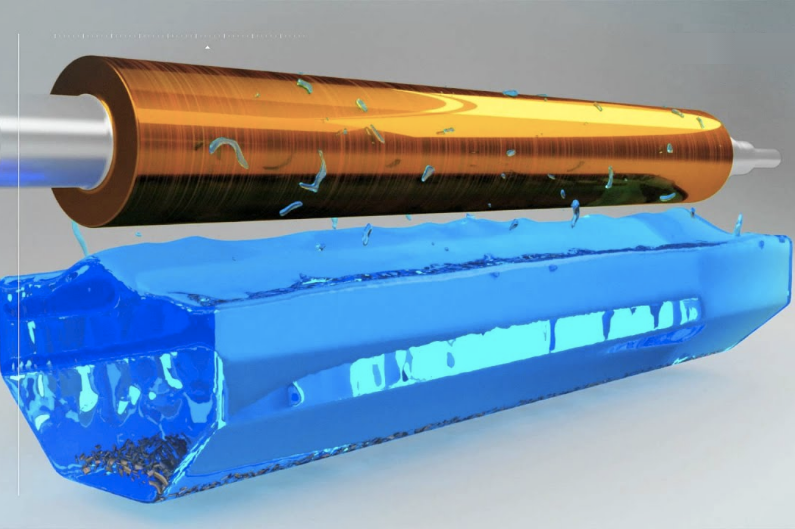

2. COPPER PLATING

The mild-steel cylinder rotates in our ACIGRAF(Italy) bath or tank filled with a copper sulphate solution. Depending on the special requirements of the gravure cylinder, electro-mechanical surface treatment completes the preparation of the base which improves engraving quality of the cylinders.

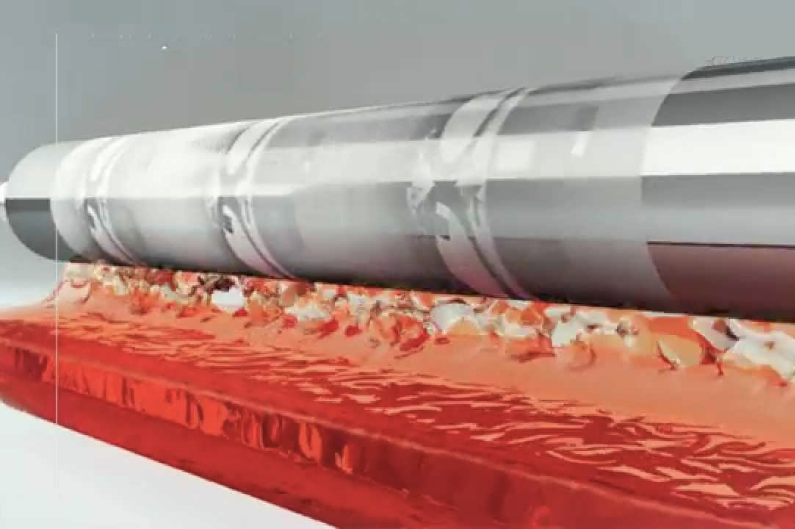

3. POLISHING & FINISHING

The copper-finished cylinder then goes through a process of polishing and finishing to achieve the required size in preparation for engraving. Our ACIGRAF (Italy) Super Perfast Machine prepares optimal quality copper surface balance to minimize the tolerance and achieve evenness of the cylinder.

4. ENGRAVING PROCESS

The cylinder rotates in HelioKlischograph K5 Engraving Machine, which can provide HelioSprint BC+ to process through high quality detailing and counter sharpness. This state of the art machine can support speeds up to 9 kHz. The motorized support with integrated autofocus camera facilitates semi-automatic cell measurement.

5. CHROME PLATING

The cylinder surface is then chrome plated in our ACIGRAF(Italy) chrome bath, which has the identical appearance to that of a copper bath and finished (polished) immediately after the cylinder has been engraved for long life of cylinders.

6. PROOFING

To ensure that cylinders meet high quality standards, proofing process has high precision best in class proofing machines. These machines ensure total registration employing the same inks and substrate which are to be used by the customer. Every proof is approved by customer for the establishment of the accurate colors using standard inks on actual substrate.

7. QUALITY ASSURANCE

Ceaseless investment in both technology and human resources has enabled Ved Graphics in upholding its commitment to quality. Our emphasis on quality is apparent not only at every stage of production process, but across all departments and functions within organization. Latest specific instruments are used to check the quality of product at different stages all through the process until final dispatch. Data captured from the quality control processes are stored in the data bank for future reference.

8. PACKAGING FOR DELIVERY

Proper packaging of cylinders is done in light weight fiber boxes for optimizing the air cargo. Delivery schedules at Ved Graphics are strictly adhered to so that the flawless product reaches your doorstep on time every time.